AS the operation control system installed and operated in Dangjin Thermal Power Plant, Ulsan Thermal Power Plant, Ilsan Combined Cycle Power Plant, and Donghae Thermal Power Plant,

it is an enterprise-standard OIS system that standardizes dozens of DCS, computer operating system, and application programs, which are different from each other in each workplace such as steelworks and large plants.

OPC communication architecture configuration for various DSC models

Configuring OPC communication architecture

Cost reduction through localization of software

With achieving standardization of symbols, operation devices, trends, alarms, events, screen configurations, etc. of all workplaces to prevent erroneous operation due to operator rotation and maximize operation efficiency

Power station OIS operation using screen

OIS execution screen

Operation Screen (Application of Enterprise Standard)

| Key Achievement |

|---|

|

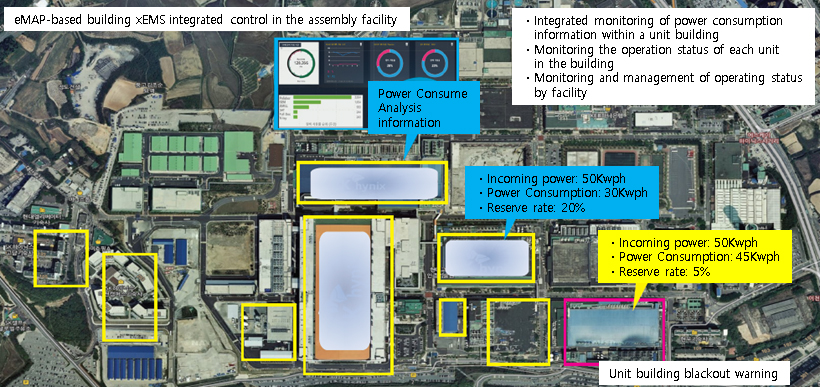

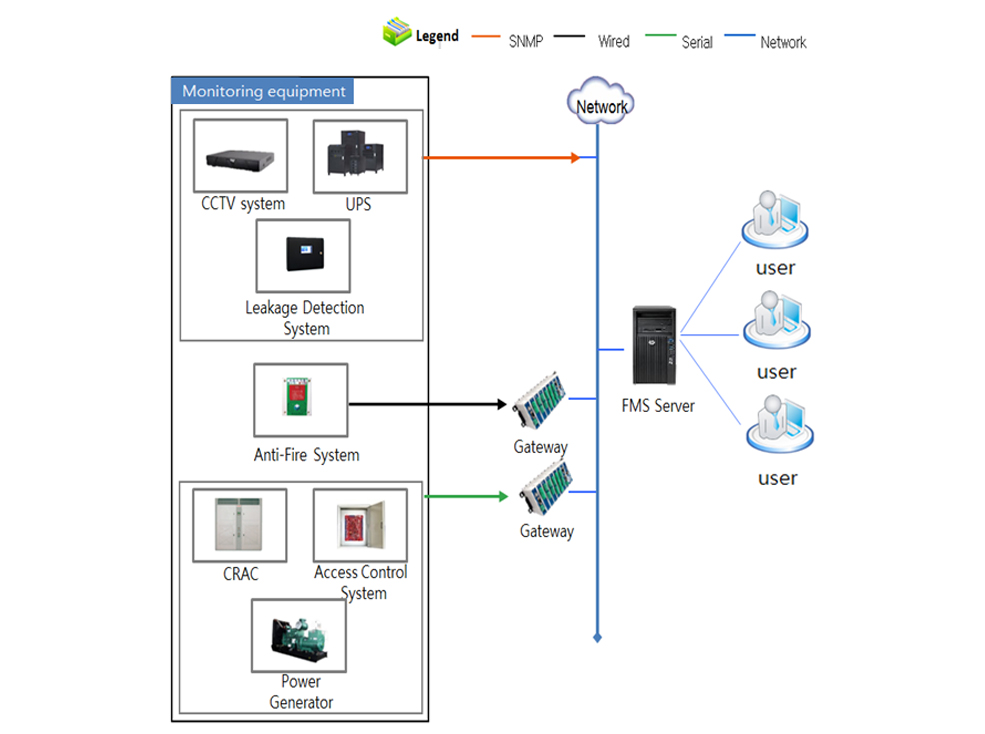

Utilizing IoT technology, it monitors operation status such as various power facilities,

air conditioning facilities, building management, network management, and environmental monitoring function through sensors.

It is an operation management system that supports continuous maintenance of continuous

and non-stop service by integrated management of infrastructure and environment such as computer room, research center, and machine room.

Topology map

Monitoring usage rate

Equipment/line performance management

Intelligent IoT devices and big data analysis system for facility safety and management

Co-worked with construction companies, local governments, facility management corporations

based on experience of PyeongChang Winter Olympics facilities management (HASLLA platform operation)

A construction company's earthquake detection project, Busan bridge safety business, and S semiconductor’s

test equipment power management business are underway

Frequency analysis of power signal

Authentication and reliability testing

Passed the reliability evaluation in 2017

Analyze operation status of semiconductor test equipment and monitor operation status

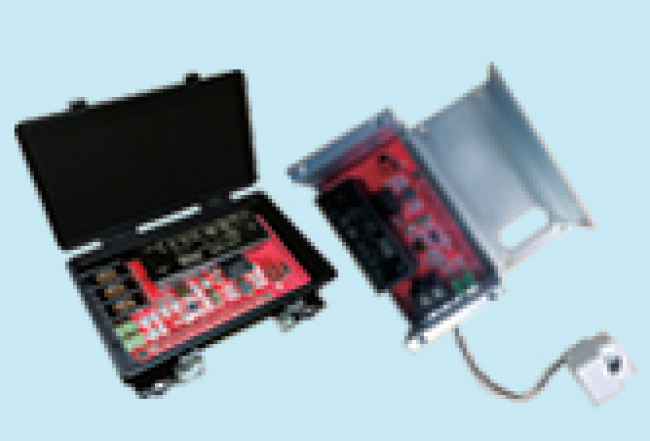

Service device

Monitoring system

Facility safety management service

< Reliability test report >

|

Example) Monitoring operation status and operation status of semiconductor test equipment